XU

Flexible Rubber

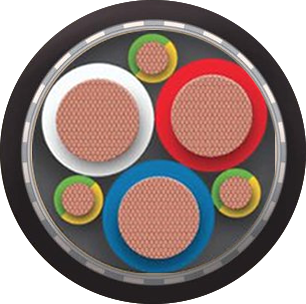

Coll. Scr. & Braid VSD/VFD

0.6/1kV 90°CInsulation X-90

|

Typical ApplicationsSuitable for flexible fixed wiring application where EMC protection is required.  Standard Core Configuration

Other Colours available on request |

Construction

Conductor Fine wire plain or tinned annealed copper to IEC 60228 and AS/NZS 1125.

Insulation LSFLEX® XL-20 (X-90), Cross-Linked, Polyethylene, Elastomeric.

Separator Polypropylene tape

Screen Copper Laminate tape

Braid Tinned Copper Wire braid(90%)

Separator Polypropylene tape

Jacket Low Friction E-RUBBER® N-30, Thermoplastic, Elastomeric, Flame Retardant. Splash resistant to oil, skydrol, petrol, acid and sea water. Resists ozone and UV. Excellent abrasion resistance. Submersible to 500 meters. Best Practice PVC. Anti-Termite/Rodent Jacket is available.

Operating Temperature

- -15°C to 90°C

Voltage Rating

- 600/1000Volts

Core Identification

- To customer specification

Jacket Colour

- To customer specification

Standards

- AS/NZS 1125

- AS/NZS 1660.5.1

- AS/NZS 1660.5.6

- AS/NZS 3008.1

- AS/NZS 3008

- AS/NZS 5000.1

- IEC 60228

- IEC 60332-1

m |

ze m² |

Ea m |

rth m² |

Min. Bend Radius mm |

Nom. Cond. OD mm |

Nom. Ins. OD mm |

Nom. Braid OD mm |

Nom. Cable OD mm |

Current Rating amp |

Approx. Wt. kg/km |

|---|

Continuous current carrying capacities are calculated assuming 40° ambient temperature in free air, flexible unenclosed touching. For other installation methods, please refer to our current ratings table.

| Conductor Comparison - TriCab versus Class 5 & 6 (approximate no.of wires) |

| Size mm² | 50 | 70 | 95 | 120 | 150 | 185 | 240 | 300 | 400 | 500 | 630 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| TriCab | 658 | 969 | 1216 | 1672 | 2052 | 2508 | 3256 | 4144 | 5368 | 6832 | 8784 |

| Class5 | 378 | 342 | 465 | 587 | 734 | 905 | 1174 | 1468 | 1958 | 1710 | 2155 |

| Class6 | 662 | 927 | 1258 | 1589 | 1987 | 1401 | 1817 | 2272 |